Concurrent Engineering Best Practices

CONCURRENT ENGINEERING DESIGN: Integrating the Best Practices for Process Improvement. Dearborn, Michigan, Society of Manufacturing Engineers. James and E.W. Daniel (1989). They named it Set-Based Concurrent Engineering (Ward et al., 1995). A year later, they described a set of 11 principles (Sobek & Ward, 1996) and have in 1999 refined and categorised them in a framework of three broad principles based on Toyota’s best practices, each with three different steps to implementing them (Sobek, et al, 1999).

Set-Based Concurrent Engineering in CMI Defence

In the second half of 2013, CMI Defence, a weapons systems manufacturer from Belgium, started to explore Set-Based Concurrent Engineering (SBCE), its advantages, principles and tools associated with the approach. This is not the first time CMI Defence came across SBCE, but it was the first time they committed to it. The implementation was kicked-off at the engineering department, later followed by a first round of global implementation. This article briefly describes the SBCE process in CMI Defence, complemented with some theoretical foundations, for readers not so familiar with the Set-Based Concurrent Engineering approach (often called Set-Based Design or simply Set-Based Engineering).

CMI Defence is one of the world’s leading companies in multifunctional, high-effect weapon systems for light and medium weight armored vehicles. CMI Defence is part of the CMI Group, which in 2014 generated nearly 900 million euro, 38% of which came from CMI Defence with the remaining 62% spread evenly among the Group’s three other sectors.

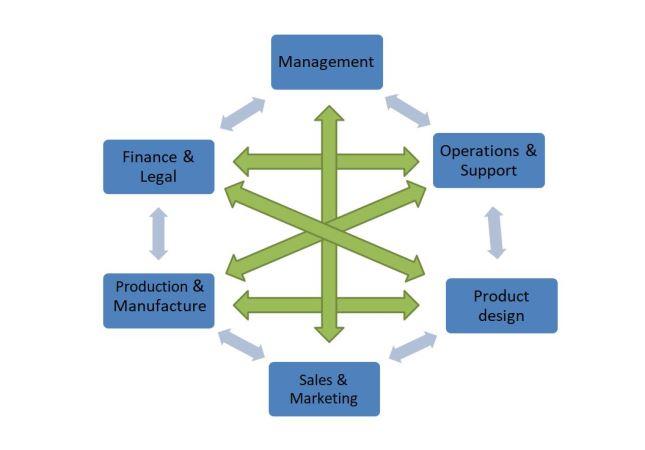

Constant demand for shorter development and lead times, including several day-to-day business issues, for instance inefficient communication, coupled with the company’s continuous growth were clear indicators that a change was needed. CMI Defence found an answer to increase its product development efficiency by applying Lean Thinking practices.

Set-Based Concurrent Engineering (SBCE) is a product development approach where multiple solutions for the same need or problem are developed in parallel. As the solutions mature through time, teams gradually narrow their respective sets of solutions based on the knowledge gained through prototypes, experiments, and tests. As the teams narrow (reduce) their set of solutions, they commit to staying within the sets so that other design teams (working on a different subsystem or managing the entire system) can rely on their communication (Sobek, et al., 1999).

How does SBCE framework in CMI Defence looks like?

Prior to the ‘Exploration Phase’, the team breaks down the product under consideration (the entire product; e.g. armored vehicle turret system) into its core subsystems (e.g. feeding system, gun, armor, etc.), where each subsystem is then assigned to a team of specialists. This enables the development teams to enter the exploration phase where they create and explore multiple concepts for their respective subsystems in parallel. These are developed for as long as factual information is needed to make a decision. Trade-offs between alternative solutions are explored and feasibility tests are carried out. Testing ensures that enough and right knowledge is generated for informative decision-making, while trade-offs indicate potentially stronger and weaker solutions.

In the second phase called ‘Set-Based Communication,’ teams look for feasible intersections between developed alternatives and rule out the inferior ones. Although some alternatives are not fit for further development, they are not discarded entirely. The ruled-out alternatives might still have interesting and valuable features, which teams can merge with stronger alternatives if/when applicable. Only when all teams are aligned and key knowledge gaps are identified, they enter the third phase, called ‘Convergence’.

‘Convergence Phase’ is a phase where sets of alternative solutions are gradually narrowed down by increasing the details and knowledge through analysis, prototyping and testing.

Welcome to downloadfreepdf.com Here you can find and Download Free Books.We have ebooks for every subject available for download. Search the website and find pdf books about Insurance, Loans, Law books for lawyers and attorneys. Download in 10 seconds Business eBooks are Premium Start a 30-day free trial of our Premium eReader, and gain access to our huge Business eBook library Try for free. Free online books download pdf. Download free books for your phone, desktop, laptop. Get your next free ebook download from Obooko: all legally available as pdf, epub books and kindle books. Free books to read and download that won’t cost you a penny. Access and every free ebook download is without charge. Enjoy as many free online novels and text books as you wish with the.

When the final sets are communicated and agreed upon, development teams commit to staying within their sets so that other teams can rely on them. In this part of the project, teams spend most of the times trying to find the answers to address and resolve the knowledge gaps that exist within their own subsystems, while at the same time ensuring their solutions are capable of seamless integration with solutions from other subsystems. These integration events are ensuring the required knowledge is created and the functionality of the system is perfected before the solution proceeds to the detailed design phase. The final phase, known as the ‘Selection Phase,’ aims at selecting the most promising system solution which will be pursued in the following stages of the product life cycle.

As a result of following the SBCE process for a medium caliber feeding system, CMI Defence developed a brand new, patent pending, design which would have, in engineering team words, very unlikely been developed using their traditional processes and tools.

CMI Defence’s Best Practices are presented and described on more than 25 pages in the Lean Product Development Best Practices book. CMI Defence’s chapter is only one out of the 10 chapters presenting the real-world application of lean product development in different innovative companies.

The hard copy of the book with the 10 cases is available for only 74.99 EUR.

CMI Defence’s Lean Product Development case is available digitally free of charge to our members.

Interested to become a member?

ABOUT THE AUTHOR(S)

Fix my drivers for free. MATIC GOLOB

Lean Analytics Association

Matic has over 5 years of experience in working with global organizations from various industrial sectors, either leading or supporting the development and introduction of bespoke lean innovation and new product development solutions. Over the past years, Matic has co-developed a framework to enable better, faster and more integrated innovation across the entire value chain, enabling companies to maximize their innovation capability and deliver truly customer-centric products and services, while minimizing the risk of market failure. 123 free movies.

Matic is a certified Service Design Thinking Facilitator, and the creator of the Set-Based Integrated Innovation Business Game co-developed with a multinational Swiss company. He completed his Master’s degree in Global Product Development and Management at Cranfield University in 2012.

Matic is a co-author of the Lean Product Development Best Practices book, and several journal and conference publications. He regularly appears as a speaker and workshop holder at various lean, product development and innovation conferences.

Best Practices Yakima

OLIVIER CARLENS

CMI Group

Olivier Carlens is a Deputy Group CTO for CMI, a Belgian diversified group involved in Defense, Energy, Industry, Environment and Services. He previously worked for the CMI Defence, a CMI Group subsidiary, and other Belgian Defense companies. His experience includes Project Management, Systems Engineering, Product Development and Innovation Management.

Olivier received a Master of Sciences in Ballistics and Weapon Engineering from the Royal Military Academy of Belgium, a MBA from Vlerick Management School and a Master of Sciences in technology Management from the Open University.

MYRNA FLORES

Lean Analytics Association

Dr. Flores has over 20 years of experience collaborating as internal or external consultant in different manufacturing and services organizations, leading several initiatives related to Lean Thinking, Business Process improvement, Six Sigma, Supply Chain, Change Management, Open Innovation, Digital Transformation and Human Centered Service Design; providing also training and coaching.

She is co-founder and president of the Lean Analytics Association (LAA) and visiting scholar at the College of Management of the Ecole Polytechnique Fédérale de Lausanne (EPFL) in Switzerland.

She carried out her Post-doc at EPFL collaborating at the Lean Product and Process (LeanPPD) FP7 European project from 2009 to 2013. She completed her PhD in 2006 at the Politecnico di Milano studying Open Innovation Models to enable Industry-University collaboration for innovation. She obtained her Master’s Degree in Manufacturing Systems in 1999 and a Bachelor’s Degree in Mechanical Engineering from Monterrey Tec (ITESM) in 1996.